Agility And Speed Take Center Stage In Merchandising

Brian and I are working on our 2021 merchandising report. This is proving to be somewhat challenging to write, as we see hundreds of container ships stalled before or at the point of entry into the United States. Even worse, the price of entry onto those ships has risen four to one hundredfold, depending on whose numbers you believe.

These price increases are being passed on to consumers, which drive the inflationary pressures we are all feeling. This begs several questions, many of which we have been talking about for months: how do we create a win-win scenario for both retailers and consumers? How do acknowledge that costs will remain high for some time to come, and there may well be additional constraints that follow: like the need for more sustainable products, less waste, and better working conditions in factories.

One solution that will help create that win-win for retailers and consumers is increasing sales of private label merchandise. The inherent higher gross margin in private label product brings to retailers is a win for them, and the lower prices caused by the absence of an external brand manager keeps consumers’ wallets somewhat safe.

Retailers know it. We asked them which features of private label were most important to them PRIOR TO the pandemic. Two-thirds report that quality and low cost were most important. But things have changed.

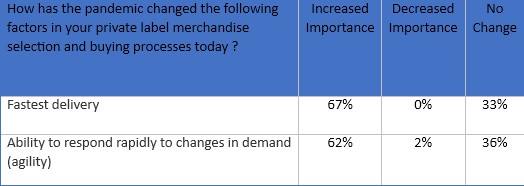

Fastest delivery and agility have moved from the middle of the “importance” pack right up to the top (Figure).

Agility Now Important To All, Along With Speed

Source: RSR Research, November 2021

The implications here are huge: it’s very difficult to achieve both speed and agility when sourcing a half a world away. And the need to switch suppliers to keep that speed going (because, well, you know, things just happen these days from fires to floods to heaven knows what) change the importance of certain technologies.

In fact, one thing we keep coming back to is the importance of Product Lifecycle Management and Sourcing technologies to support retailers’ private label initiatives. Certainly it’s desirable to return to near-sourcing – and create flexibility in the factories ports they use, but making rapid changes come hard across two dimensions:

- Certainly, there’s a corporate culture problem. “This is the way we’ve always done it” is a not-unusual retail objection, and shifting private label sources and technologies fits right in that paradigm. Solving this takes strong leadership at the C-level, and retailers know it

- Then there’s a technology problem. Absent PLM and sourcing technologies, the production education process for new factories will take as long as languishing outside a full port. PLM will provide the specificity that will shorten that education process. Our data also tells us that using these technologies has already decreased time-to-volume by at least 10% for over 50% of respondents. Many have achieved a 25% reduction. These numbers matter. They make the difference between late arrival and a markdown or rapid sales at full price.

There’s a lot more data we’ve uncovered in this report. Some of the information may prove to be too late for the upcoming all-important holiday season. Truth be told, it is almost upon us. Still, we believe it should be required reading for all merchants. The world is not going to return to a steady state for some time, and if you believe that climate change is in full swing, it may be longer than just 2023.

Retail remains a holistic business, despite the siloing of large organizations. When we speak of the customer experience (CX) it crosses all aspects of the business. This merchandising report will touch on many of those aspects while putting the focus solidly on getting the right product into shoppers’ hands as quickly as possible, with a minimum of resource and time wasting. The report is coming soon. We can’t wait for you to see it.